Everything but the ignition switch taken out. Need to work out how to remove the ignition switch.

Radio:

Heater:…

Archive:

1967 Pontiac Firebird

Shocks and leaf springs.

Took out the rear shocks and leaf springs. Someone in the past did a rather shitty repair for one of the rear shocks where it had rotted and fallen through the trunk pan mounts, they made a bodge plate and bolted it to the rear frame. To get the leaf springs out was a little tricky; a couple of the front bracket mount bolts just turned as they had separated…

Took out rear axle.

Took out the rear axle assembly. This was just a case of un-attaching the shocks then unclamping the leaf springs, the traction bar was already unbolted from the body. The leaf springs are being a little stubborn, so I separated them under the car and am going to take them out later.

Before:

Before / after:

Before / after:

Axle Assembly:…

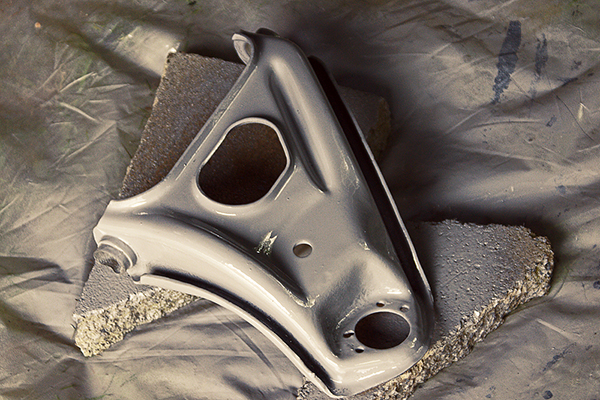

Removing upper control arm shaft and bushings.

Pictures say it all. Just use a chisel and hammer.

This metal outer sleeve gets replaced with a new bushing, so the damage doesn’t matter. The edge of the control arm shaft hole is burred, so will need filing down.…

Removing lower control arm ball joints and bushings.

Removing lower control arm ball joints:

Place the old castle nut upside down on the ball joint, and hit hard with a hammer. After successive knocks the ball joint backing plate will fall off and the ball joint will fall through.

The removal process is not finished, it is continued here. Or, see my how-to article.

Removing lower control arm bushings:

If after brute force applied…

Cavity waxing.

For this I used Bilt Hamber Dynax S-50 (anti-corrosion for cavities). Only way to tell if it’s really any good is to wait a few years. It certainly applied easily and got good coverage, and is definitely water repellent. When it dries it has a rubbery flexible feeling.

Subframe inside. Before and After:…

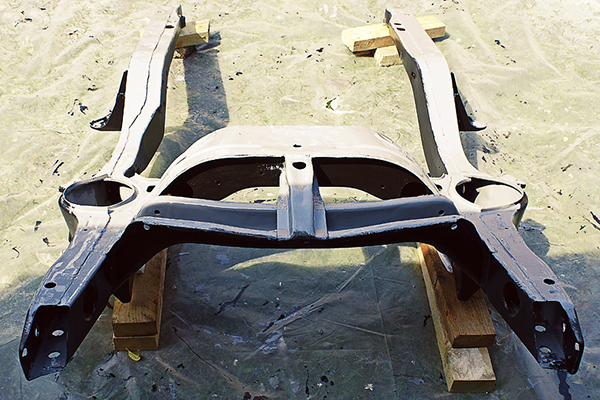

Painting subframe (underneath).

POR-15 (rust preventative base coat):

The base coat is really good stuff. Goes a long way and all brush strokes smooth out when drying.

POR-15 Chassis-Coat (UV protection top coat):

The top coat is not quite as good as the base. It covers about half as much, and brushes strokes are inevitable. It does have a nice finish – colour and sheen – to it though. Once the subframe…

;)

;)

;)

;)